Everything that we design, create, and fabricate happens in-house. What does that mean? It means when you receive your product, the whole thing was done in our studio and in our shop. This allows us to have more control over the process and helps cut off any middle man; making our products cheaper than the competition and still high quality.

But what does that look like?

Step One: Designing

We have brilliant designers that can both design logos for your team and make them fit elegantly on your helmet. Then we design the layout for printing

Step Two: Printing

We use some of the best printers to print on the highest quality vinyl. We use 20mil thick-flexible vinyl to ensure strength and quality

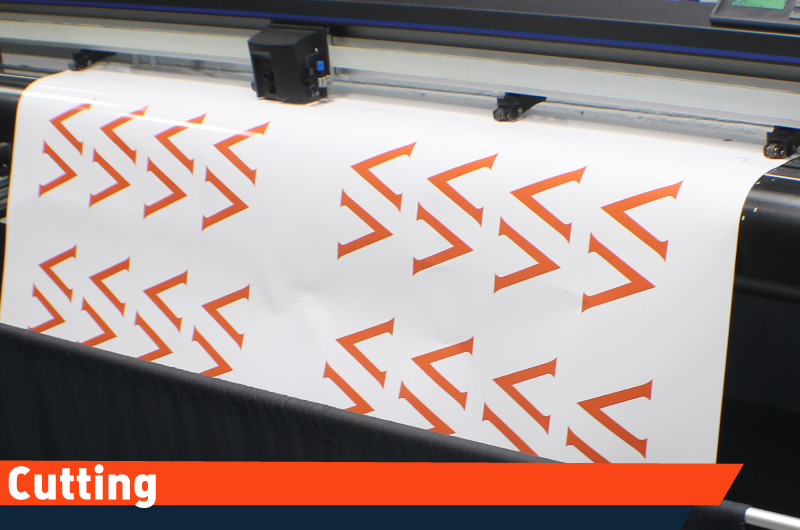

Step Three: Cutting

Clean cuts are very important, for both the look and the process. Using the highest end cutting technology ensures we get those clean cuts

Step Four: Weeding

After we print and cut, we weed the vinyl. Weeding vinyl is when you remove the unwanted vinyl, which is why a clean cut is so important. If the cut doesn’t go all the way through then it can cause the vinyl to tear when weeding

Step Five: Laminating

Once the vinyl has been weeded, we laminate them with thick laminate. This protects them from getting ruined by weather, impact, whatever can come at them

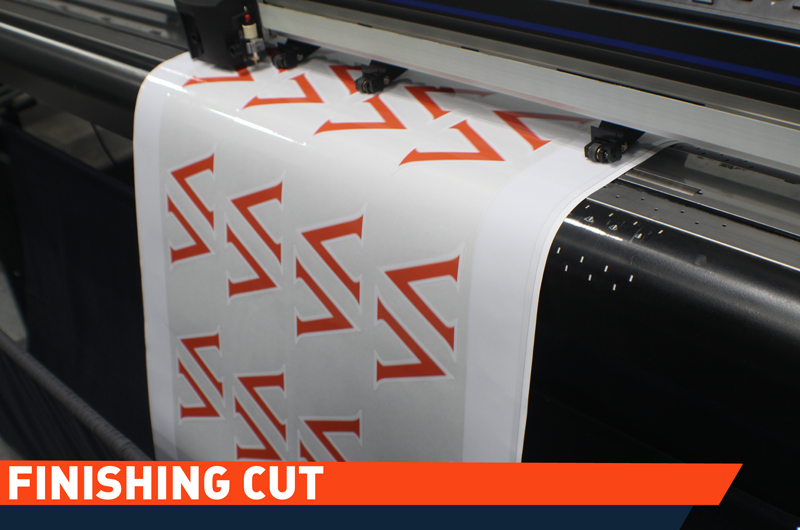

Step Six: Finishing Cut

After laminating we put the sheet through cutting one last time to cut out the finished decals. Creating clean cuts allows the decals to be both professional looking and easy to remove

Last step

Cutting the decals into their individual squares, putting them in some envelopes, ready to be picked up